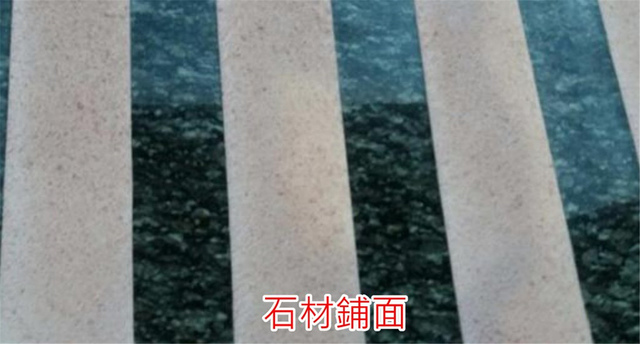

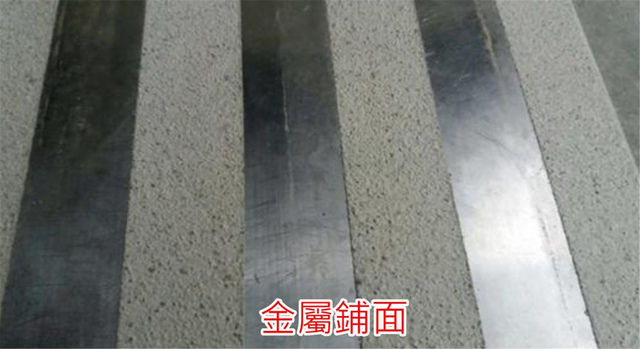

1. Applicable scope: Can be used on manhole covers, stainless steel sheet metals, all kinds of metal, glass, wood, all kinds of pedestrian walkways, quartz floor tiles and other floor tiles, glass plates, ditch grilles, and pavement markings.

2. The new material is composed of polymer cementing material and a variety of inorganic minerals, and does not contain organic solvents.

3. Excellent weather resistance, acid resistance, durable in sunlight and rain, does not discolor or pulverize.

4. Non-toxic, does emit secondary pollution, and is friendly to the environment.

5. Leave for one hour after spraying. British Pendulum Number (BPN): > 65.

Instructions for use:

1. This product contains 800 grams of ceramic powder and 200 grams of polymer binder. Coverage with a spray gun is 0.5 square meters, and brushing area with a roller brush is 1 square meter.

2. Operation mode: Spray gun and roller brush.

3. Mixing materials: Use an electric mixer to stir the polymer cementing material with the anti-slip powder material for about one minute, and stir to mix fully. If too thick after stirring, the product can be thinned by adding water, but it should not exceed 3% of the solution. Excessive dilution will affect the anti-slip effect of the coating.

4. If using a spray gun, prepare the required machines and tools: Generator (when there is no power supply), air compressor with at least 2.5HP, electric mixer, and a spray gun with an inner nozzle diameter of at least 2 mm (an inner nozzle with a diameter of 3.8 mm is recommended). The pressure of the spray gun should be controlled at about 3 kg/m2. Spray the well-mixed product on the surface of the material with a high-pressure spray gun.

5. If using a roller brush, prepare the required tools: Roller brush, paint tray, and electric mixer. Apply the well-mixed product evenly on the surface of the material with a roller brush.

6. Drying time: About one hour (initial setting in 16 minutes).

7. Remove water, grease, rust, sludge, corrosive salts, and other dirt from the surface of the object to coat before spraying or applying the product to ensure best results.

Attention:

1. Thickness: Dry film thickness greater than 1 mm.

2. Product can be stored for at least half a year in normal conditions.

3. Bottled water-based latex resin should be protected from sunlight, and ceramic mineral powder should be protected from moisture and agglomeration.

Color: Black, gray, white, red, yellow, blue, and green.